Sewer Nozzles

Sewer nozzles are specialized tools used in the field of wastewater management and maintenance. These nozzles are designed to efficiently and effectively clean, unclog, and maintain sewer and drain systems, whether they are in municipal sewer lines, industrial pipelines, or residential plumbing. In this article, we will explore the importance, types, applications, methods, and benefits of sewer nozzles.

Importance of Sewer Nozzles:

Sewer nozzles play a critical role in maintaining the functionality and hygiene of sewer and drain systems. Their importance can be summarized as follows:

-

Preventative Maintenance: Regular cleaning with sewer nozzles helps prevent blockages and backups, reducing the risk of costly emergency repairs and sewer overflows.

-

Improved Flow: Sewer nozzles efficiently remove debris, sediment, and grease buildup from pipes, ensuring optimal flow and preventing slow drains.

-

Hygiene and Health: Proper sewer and drain maintenance using nozzles help prevent foul odors, the breeding of harmful bacteria, and the spread of diseases associated with wastewater.

-

Cost Savings: Regular maintenance using sewer nozzles is cost-effective in the long run, as it extends the lifespan of sewer systems and reduces the need for extensive repairs.

Types of Sewer Nozzles:

Sewer nozzles come in various types, each designed for specific applications and cleaning tasks:

-

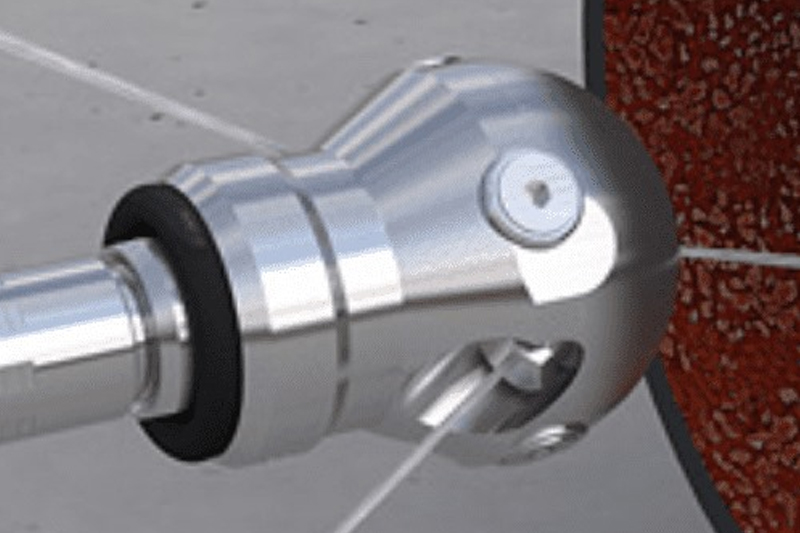

Rotating Nozzles: These sewer nozzles have spinning or rotating heads that create a powerful, even spray pattern. They are effective for removing tough clogs and debris.

-

Penetrating Nozzles: Penetrating nozzles are designed to break through blockages and remove deposits on pipe walls. They often have a single forward-firing jet.

-

Flushing Nozzles: Flushing nozzles have multiple rear-facing jets that push debris and sediment out of the pipe as they advance forward. They are useful for cleaning long stretches of sewer lines.

-

Warthog Nozzles: Warthog-style nozzles use rear-facing, high-velocity jets to propel the nozzle through pipes while simultaneously cleaning them. They are ideal for heavily clogged lines.

-

Chain Flail Nozzles: Chain flail nozzles have rotating chains or blades that scrape away stubborn blockages and root intrusions.

Applications of Sewer Nozzles:

Sewer nozzles are widely used in various applications across different industries:

-

Municipal Sewer Maintenance: Sewer nozzles are employed by municipal authorities to clean and maintain sewer lines, preventing blockages and ensuring smooth wastewater flow.

-

Industrial Pipelines: In industrial settings, sewer nozzles are used to clean and maintain pipelines, which may transport various fluids and waste materials.

-

Residential Plumbing: Plumbing professionals use sewer nozzles to clear blockages in residential drain lines, ensuring efficient water and waste flow.

-

Stormwater Drain Cleaning: Sewer nozzles are used to clean stormwater drains, preventing flooding and water contamination during heavy rainfall.

-

Septic System Maintenance: For septic tank systems, sewer nozzles can be used to remove sludge buildup and prevent system failures.

Methods of Sewer Nozzle Operation:

Sewer nozzles operate based on the following principles:

-

High-Pressure Water Supply: A high-pressure water source, such as a jetter or pressure washer, supplies pressurized water to the sewer nozzle.

-

Nozzle Design: The nozzle’s design and configuration determine the type of spray pattern and the direction of water jets.

-

Insertion and Propulsion: The sewer nozzle is inserted into the sewer or drain line and, depending on the type, may be propelled by the force of the water jets or manually pushed through the pipe.

-

Cleaning Action: The high-pressure water jets generated by the nozzle dislodge and flush away debris, grease, roots, and other obstructions.

-

Thorough Inspection: After cleaning, sewer lines are often inspected using cameras to ensure complete removal of blockages and assess the condition of the pipes.

Benefits of Sewer Nozzles:

-

Effective Cleaning: Sewer nozzles effectively remove blockages, sediments, and debris, ensuring proper wastewater flow.

-

Preventative Maintenance: Regular cleaning with sewer nozzles helps prevent costly emergency repairs and system failures.

-

Cost Savings: Proper maintenance with sewer nozzles extends the lifespan of sewer systems, reducing the need for expensive repairs or replacements.

-

Environmental Protection: Sewer nozzles help maintain the integrity of wastewater systems, reducing the risk of spills and contamination of natural water sources.

-

Health and Hygiene: By preventing blockages and backups, sewer nozzles help maintain proper hygiene standards and reduce the risk of disease transmission.

In conclusion, sewer nozzles are indispensable tools for maintaining the functionality and hygiene of sewer and drain systems in various industries. Proper use of sewer nozzles ensures efficient wastewater flow, prevents costly repairs, and contributes to a cleaner and safer environment.