HPWJ Hose & Lance

Importance of Connectors:

Connectors are essential for several key reasons:

- Seamless Connection: They provide a secure and reliable link between various components of cleaning equipment, ensuring smooth and uninterrupted operation.

- Leak Prevention: Properly designed and maintained connectors prevent fluid leaks, which can be wasteful, messy, and potentially hazardous, especially when dealing with chemicals or hot water.

- Versatility: Connectors come in various types and sizes to accommodate different cleaning machines, nozzles, hoses, and wands, making them highly adaptable to various applications.

- Ease of Use: Well-designed connectors are user-friendly and enable quick and hassle-free assembly and disassembly of cleaning equipment.

Connectors are crucial components that facilitate the efficient operation of various cleaning equipment, including pressure washers, steam cleaners, industrial vacuums, and more. These connectors serve as the link between hoses, nozzles, wands, and the cleaning machine itself, ensuring a secure and leak-free connection. In this article, we will explore the importance, types, applications, methods, and benefits of connectors in cleaning machine services.

Types of Connectors:

Several types of connectors are commonly used:

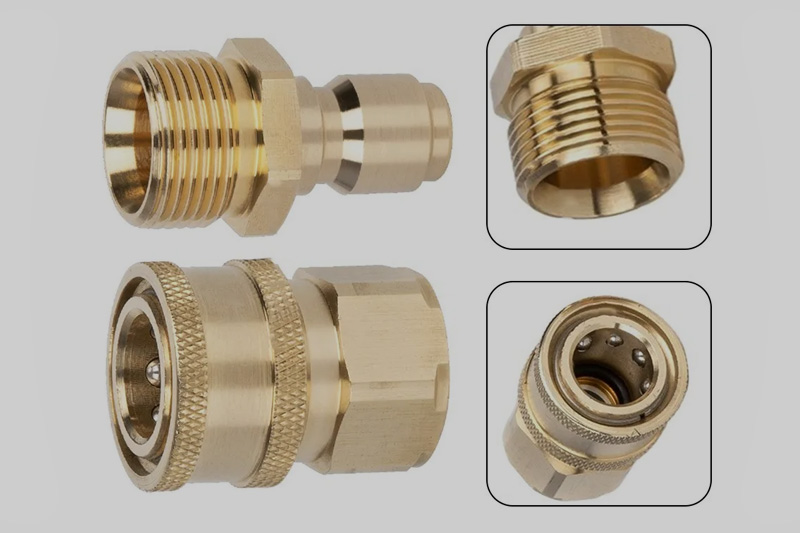

- Quick-Connect Couplings: These connectors allow for fast and tool-free attachment and detachment of hoses, nozzles, and wands, enhancing the efficiency of cleaning machines.

- Threaded Connectors: Threaded connectors use threads to screw hoses, nozzles, or wands onto the cleaning machine or other components. They provide a secure and leak-resistant connection.

- Camlock Fittings: Camlock connectors use a cam mechanism to secure hoses and pipes. They are popular in industrial cleaning applications for their reliability and ease of use.

- Push-to-Connect Fittings: These connectors allow for straightforward push-in connection of hoses, reducing assembly time and effort.

- Bayonet Connectors: Bayonet-style connectors use a twist-and-lock mechanism to secure components in place, providing a reliable and quick connection.

Applications of Connectors:

Connectors are used in a wide range:

- Pressure Washers: Connectors facilitate the attachment of high-pressure hoses, wands, and nozzles to pressure washer units, enabling effective cleaning of surfaces.

- Steam Cleaners: Steam cleaning machines use connectors to link hoses and nozzles to deliver high-temperature steam for cleaning and disinfection.

- Industrial Vacuums: Connectors are vital for connecting hoses and attachments to industrial vacuum cleaners for debris and liquid suction.

- Car Wash Systems: Car wash equipment relies on connectors to secure hoses, brushes, and spray nozzles for vehicle cleaning.

- Floor Scrubbers: Floor scrubbing machines utilize connectors to link hoses and brushes or pads for efficient floor cleaning.

Methods of Connector Installation and Use:

Proper installation and use of connectors are essential for safe and efficient operation:

- Selection: Choose connectors that are compatible with the cleaning machine and accessories in terms of size, type, and material.

- Assembly: Follow the manufacturer’s instructions for connecting hoses, wands, and nozzles to the cleaning machine using the appropriate connectors.

- Maintenance: Regularly inspect connectors for wear, damage, or leaks. Replace any damaged connectors promptly to prevent fluid loss or equipment damage.

- Sealing: Ensure that threaded connectors are properly sealed with thread tape or sealing compounds to prevent leaks.

Methods of Connector Installation and Use:

Proper installation and use of connectors are essential for safe and efficient operation:

- Selection: Choose connectors that are compatible with the cleaning machine and accessories in terms of size, type, and material.

- Assembly: Follow the manufacturer’s instructions for connecting hoses, wands, and nozzles to the cleaning machine using the appropriate connectors.

- Maintenance: Regularly inspect connectors for wear, damage, or leaks. Replace any damaged connectors promptly to prevent fluid loss or equipment damage.

- Sealing: Ensure that threaded connectors are properly sealed with thread tape or sealing compounds to prevent leaks.

Benefits of Connectors:

- Efficiency: Connectors streamline the setup and use of cleaning machines, reducing downtime and increasing productivity.

- Safety: Secure connectors minimize the risk of accidents and injuries due to unexpected disconnections or leaks.

- Cost Savings: Proper connectors prevent fluid wastage, reducing operational costs and conserving resources.

- Versatility: Connectors allow for the use of various cleaning attachments, enhancing the versatility of cleaning machines.

- User-Friendly: Well-designed connectors make it easier for operators to set up and operate cleaning equipment.

In conclusion, connectors for cleaning machines are fundamental components that ensure the efficiency, safety, and versatility of various cleaning equipment used in industries and commercial settings. Proper selection, installation, and maintenance of connectors are essential for maximizing the performance and longevity of cleaning machines while minimizing the risk of leaks or accidents.